Introduction

When it comes to breathable and cushioned fabrics, sandwich fabric is one of the most innovative materials available today. Whether used in sportswear, footwear, backpacks, or even automotive seating, this three-layer structured textile provides ventilation, support, and durability, making it a versatile choice across multiple industries.

But what exactly is sandwich fabric, and why is it so widely used? In this guide, I’ll break down its structure, benefits, and the best ways to use it.

What You’ll Learn in This Guide

✔ What sandwich fabric is and how it’s constructed

✔ The key characteristics that make it ideal for cushioning and breathability

✔ How sandwich fabric compares to other materials like memory foam and mesh fabric

✔ Its best applications in clothing, home textiles, and industrial products

What is Sandwich Fabric?

Sandwich fabric, also known as 3D spacer fabric, is a high-performance textile with a three-layer structure designed for breathability, support, and flexibility. This innovative fabric is widely used in sportswear, footwear, backpacks, and even medical products due to its lightweight and cushioning properties.

📌 Three-Layer Structure of Sandwich Fabric

| Layer | Description | Function |

| Top Layer | Breathable mesh fabric | Enhances airflow and ventilation |

| Middle Layer | Spacer yarns (polyester or synthetic fibers) | Provides cushioning and support |

| Bottom Layer | Durable woven or knit fabric | Adds stability and structural integrity |

✅ Key Benefit: The spacer yarns in the middle layer create air pockets, making the fabric highly breathable and shock-absorbent.

📌 Common Materials Used

- Polyester (most common) – Lightweight, durable, and moisture-resistant.

- Nylon – More flexible and abrasion-resistant.

- Spandex blends – Adds stretchability for activewear and compression applications.

🎥 Recommended YouTube Video

📌 How Sandwich Fabric Works – 3D Spacer Mesh Technology

🎬 A video explaining the structure and benefits of sandwich fabric in different industries.

Characteristics of Sandwich Fabric

Sandwich fabric is designed for comfort, durability, and ventilation, making it one of the most versatile materials in modern textile applications. Below are its key characteristics:

📌 1. Breathability & Moisture Control

- The mesh top layer and air pockets in the middle allow excellent airflow, keeping the fabric cool and dry.

- Ideal for sportswear, shoes, and seat cushions, as it helps prevent sweat buildup.

📌 2. Cushioning & Shock Absorption

- The spacer middle layer acts as a buffer, providing shock absorption in shoes, backpacks, and upholstery.

- Used in orthopedic products, such as medical cushions and ergonomic chairs, for better support.

📌 3. Lightweight & Flexible

- Lighter than foam-based materials but still offers structural support.

- Provides flexibility and stretch, making it ideal for activewear and accessories.

📌 4. Durability & Resistance

- Made from synthetic fibers like polyester or nylon, making it abrasion-resistant and long-lasting.

- Resists wrinkles, shrinking, and deformation, even after extended use.

📌 5. Antimicrobial & Easy to Clean

- Some sandwich fabrics are treated with antimicrobial coatings to reduce odor and bacteria buildup.

- Machine washable and dries quickly, making it a low-maintenance material.

🎥 Recommended YouTube Video

📌 Why Sandwich Fabric is a Game-Changer for Activewear & Footwear

🎬 A quick explainer on how sandwich fabric enhances comfort, durability, and breathability in modern textiles.

How is Sandwich Fabric Made?

The manufacturing process of sandwich fabric involves advanced knitting or weaving techniques to create its three-layered structure, ensuring breathability, flexibility, and durability.

📌 1. Three-Layer Weaving or Knitting Process

- Warp or Weft Knitting Machines – Used to interconnect the top, middle, and bottom layers while maintaining airflow.

- Spacer Yarn Integration – The middle layer is created using spacer yarns, forming air pockets for better cushioning and ventilation.

📌 2. Types of Sandwich Fabric

| Type | Composition & Features | Best Uses |

| Basic Sandwich Mesh | Standard three-layer structure | Sportswear, backpacks |

| Elastic Sandwich Fabric | Contains spandex for stretchability | Compression wear, medical braces |

| High-Density Sandwich Fabric | Thicker cushioning and extra durability | Automotive seats, orthopedic cushions |

📌 3. Finishing & Treatments

To enhance performance, sandwich fabric can undergo special finishing treatments, such as:

- Moisture-wicking coating – Helps draw sweat away from the body.

- Antimicrobial treatment – Reduces bacteria and odor buildup.

- UV protection finish – Increases durability against sun exposure (used in outdoor gear and car seats).

🎥 Recommended YouTube Video

📌 How Sandwich Fabric is Made – Advanced Spacer Mesh Technology

🎬 A behind-the-scenes look at how sandwich fabric is manufactured for sports, fashion, and industrial applications.

Uses & Applications of Sandwich Fabric

Thanks to its breathability, cushioning, and durability, sandwich fabric is widely used across fashion, sportswear, automotive, and medical industries.

📌 1. Clothing & Sportswear

Sandwich fabric is a popular choice in apparel where ventilation and flexibility are essential.

| Garment Type | Why Sandwich Fabric is Used |

| Athletic Shoes & Insoles | Shock-absorbing, breathable, and lightweight |

| Sportswear & Activewear | Moisture-wicking, quick-drying, and stretchable |

| Compression Gear & Medical Braces | Elasticity and structural support for injury prevention |

| Baby Stroller Cushions & Carriers | Soft, padded support for comfort and safety |

✅ Best for: Footwear, sportswear, and baby products, thanks to its breathability and cushioning.

📌 2. Industrial & Home Applications

Beyond fashion, sandwich fabric is also used in home textiles and industrial products for comfort and ventilation.

| Application | Why It’s Ideal |

| Automotive Seat Covers & Cushions | Reduces heat buildup and provides padding |

| Backpacks & Travel Bags | Lightweight, durable, and moisture-resistant |

| Mattresses & Office Chairs | Breathable padding for enhanced comfort |

✅ Key Advantage: Long-lasting and lightweight, making it perfect for ergonomic seating and protective padding.

🎥 Recommended YouTube Video

📌 Why Sandwich Fabric is Used in High-Performance Gear

🎬 A detailed breakdown of how sandwich fabric is used in sports and industrial applications.

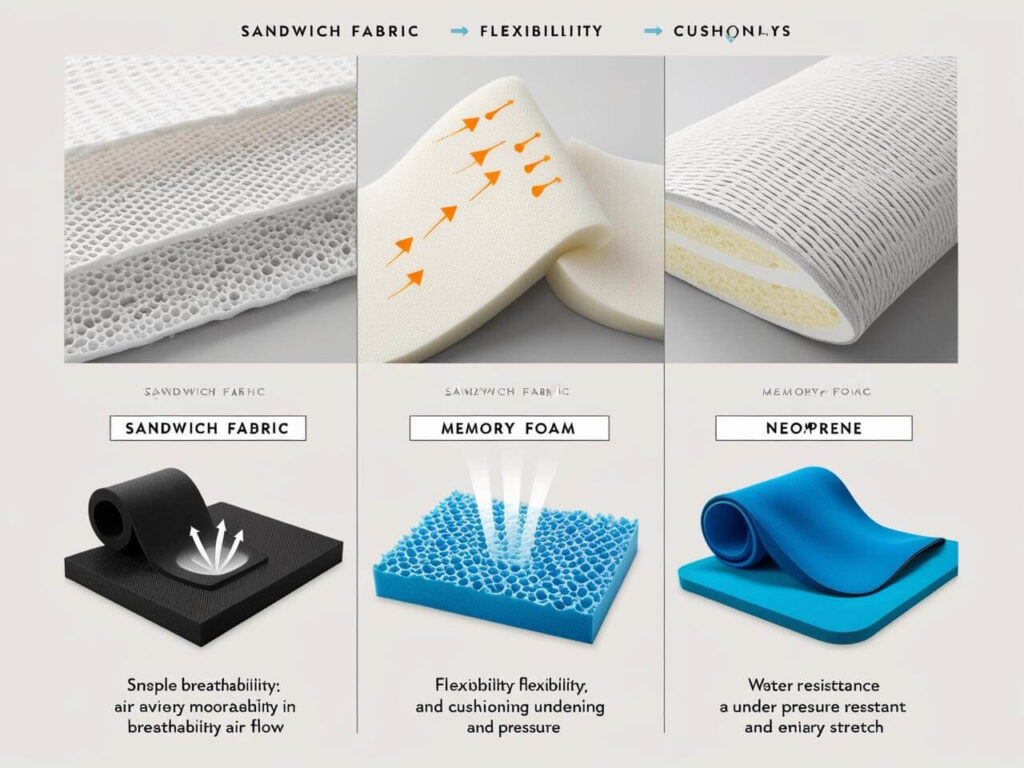

Sandwich Fabric vs Other Fabrics

To understand why sandwich fabric is widely used, let’s compare it to other materials such as mesh fabric, memory foam, and neoprene.

📌 1. Sandwich Fabric vs. Mesh Fabric

| Feature | Sandwich Fabric | Mesh Fabric |

| Structure | Three-layered with a spacer middle | Single-layer open weave |

| Breathability | High, with air pockets for ventilation | High, but lacks cushioning |

| Cushioning & Support | Provides softness and shock absorption | Minimal cushioning |

| Best Use | Sportswear, shoes, backpacks, seat covers | Lightweight athletic gear, bags, caps |

✅ Key Takeaway: Sandwich fabric offers both breathability and cushioning, whereas mesh fabric is purely for ventilation.

📌 2. Sandwich Fabric vs. Memory Foam

| Feature | Sandwich Fabric | Memory Foam |

| Breathability | High, allows airflow through the layers | Low, traps heat |

| Flexibility | Lightweight and retains shape | Molds to body shape, but can feel dense |

| Durability | More resistant to compression and wear | Can break down over time |

| Best Use | Sportswear, shoes, travel gear | Mattresses, pillows, orthopedic supports |

✅ Key Takeaway: Memory foam provides better contouring, but sandwich fabric is more breathable and durable.

📌 3. Sandwich Fabric vs. Neoprene

| Feature | Sandwich Fabric | Neoprene |

| Water Resistance | Not waterproof, but quick-drying | Waterproof and insulating |

| Flexibility & Comfort | Lightweight and breathable | Thick, stretchy, and snug-fitting |

| Best Use | Shoes, backpacks, automotive seats | Wetsuits, laptop sleeves, medical braces |

✅ Key Takeaway: Neoprene is better for water resistance and insulation, whereas sandwich fabric is superior for breathability and lightweight comfort.

🎥 Recommended YouTube Video

📌 Sandwich Fabric vs. Memory Foam – Which is Better?

🎬 A comparison of cushioning materials for sportswear, footwear, and ergonomic products.

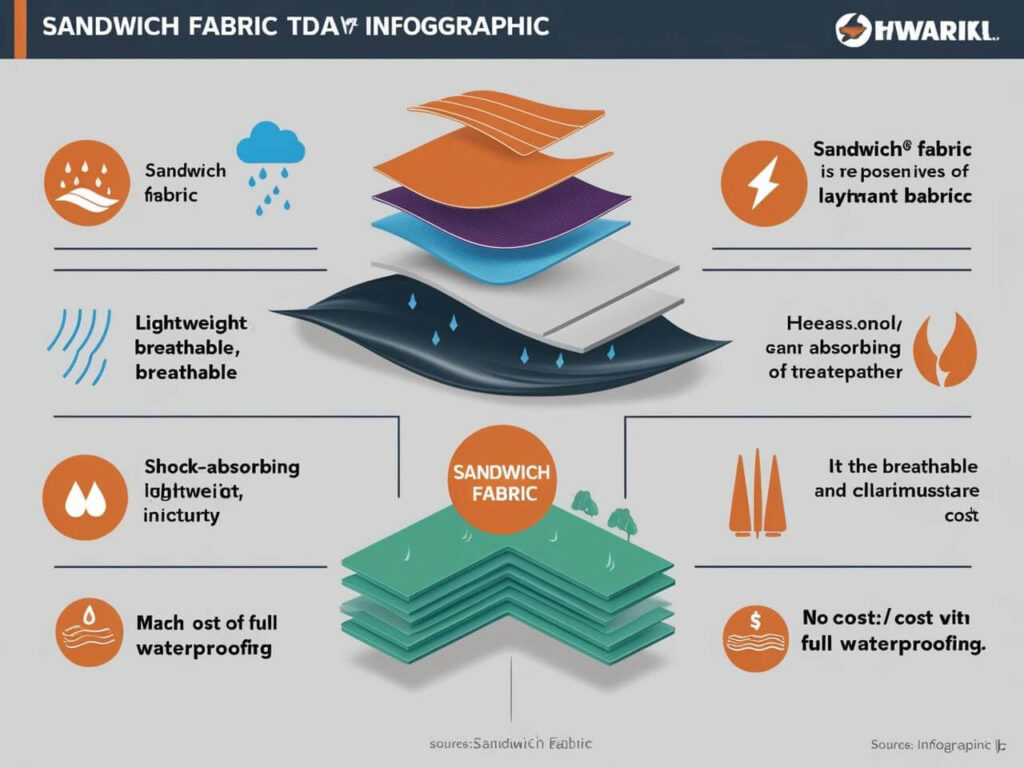

Pros & Cons of Sandwich Fabric

While sandwich fabric is a highly versatile and functional textile, it has its advantages and limitations. Below is a breakdown of its pros and cons:

📌 1. Advantages of Sandwich Fabric

✅ High Breathability – The three-layer mesh structure allows excellent airflow, making it perfect for sportswear and footwear.

✅ Cushioning & Shock Absorption – The spacer middle layer provides padding, reducing impact in shoes, backpacks, and seat cushions.

✅ Lightweight & Flexible – Less dense than foam, making it comfortable and easy to integrate into different products.

✅ Moisture-Wicking & Quick-Drying – Helps keep the material dry and odor-free, especially in sports gear and car seats.

✅ Durable & Wrinkle-Resistant – Retains shape and structure even after frequent use.

✅ Easy to Maintain – Machine washable and fast-drying, requiring minimal care.

📌 2. Disadvantages of Sandwich Fabric

❌ Less Contouring Than Memory Foam – While it provides support, it doesn’t mold to the body like memory foam.

❌ Not Fully Waterproof – Water-resistant, but not completely waterproof, unlike neoprene.

❌ Higher Production Cost – Due to its three-layer knitting technology, higher-quality sandwich fabrics can be expensive.

❌ Limited Softness – Some versions may feel slightly rougher compared to cotton or plush fabrics.

🎥 Recommended YouTube Video

📌 The Pros & Cons of Sandwich Fabric – Is It Right for You?

🎬 A short video outlining the advantages and limitations of sandwich fabric for different applications.

FAQs: Everything You Need to Know About Sandwich Fabric

To address common questions about sandwich fabric, here are concise and informative answers optimized for search intent.

❓ Is sandwich fabric good for summer?

✔ Yes! The breathable mesh structure allows for excellent airflow, making it ideal for summer sportswear, shoes, and seat covers.

❓ What is the difference between sandwich fabric and memory foam?

✔ Sandwich fabric is lighter, more breathable, and moisture-wicking, while memory foam provides better contouring and support but can trap heat.

❓ Can sandwich fabric be washed?

✔ Yes! Most sandwich fabrics are machine washable and quick-drying, but it’s best to air dry them to preserve their structure.

❓ Is sandwich fabric waterproof?

✔ No. While it has moisture-wicking properties, sandwich fabric is not fully waterproof. For water-resistant options, neoprene or coated sandwich fabrics work better.

❓ What is sandwich fabric best used for?

✔ Most commonly used for:

- Sportswear & activewear (breathable & moisture-wicking)

- Shoes & insoles (cushioning & shock absorption)

- Backpacks & luggage (lightweight & durable)

- Automotive seat covers (ventilation & comfort)

- Medical cushions & orthopedic supports (support & pressure relief)

🎥 Recommended YouTube Video

📌 Sandwich Fabric Explained – Common FAQs

🎬 A quick guide answering the most frequently asked questions about sandwich fabric.

Final Thoughts: Why Sandwich Fabric is a Smart Choice

Sandwich fabric is a highly versatile textile known for its breathability, cushioning, and lightweight durability, making it a top choice for activewear, footwear, automotive seating, and more. Whether you’re looking for a shock-absorbing insole, a breathable sports shirt, or a comfortable car seat cover, sandwich fabric offers the perfect balance of support and ventilation.

✔ Key Takeaways

✅ Highly breathable & moisture-wicking – Keeps the material cool and dry.

✅ Cushioned & shock-absorbing – Provides comfort and support in shoes, backpacks, and chairs.

✅ Lightweight yet durable – Less dense than foam, but long-lasting.

✅ Easy to maintain – Machine washable, quick-drying, and resistant to wear and tear.

✅ Ideal for sports, automotive, and medical applications – Used in sportswear, ergonomic cushions, baby products, and industrial gear.

If you’re considering sandwich fabric for your next project or product purchase, it’s a modern, breathable, and highly functional material that enhances comfort and durability.