Manufacturing Process of

Knitting Fabric

It all starts with yarns and continuous improvements on every knitting steps for offering different fabric structures to make all your knitting ideas into reality.

PROCESS

HAVE A LOOK INTO OUR

MANUFACTURING PROCESS

With abundant resources in yarns, knitting machines, dyeing and finishing houses, Fabknitter can provide whole package fabric solutions. We build up the vertical integration consistent producing processes system from Yarns → Knitting → Dyeing → Finishing.

Design

Offer trendy and personalized fabric designs, tailored to bring their fabric ideas to life.

YARN TREATMENT

We source high-quality &eco-friendly yarns, ensuring premium material selection.

DYEING

We choose eco-friendly dye houses to achieve vibrant colors and comply with environmental standards.

FINISHING

Our state-of-the-art techniques enhance fabric performance and ensure customer satisfaction.

Quality Control

We rigorously test and inspect each fabric to meet international quality standards.

FABRIC DESIGN

Our experienced design team transforms customer requirements into exceptional knitted fabrics. Through collaboration and advanced software, we create conceptual designs with diverse colors, patterns, and textures, ensuring client satisfaction at every stage.

With cutting-edge manufacturing facilities and skilled technicians, we bring fabric designs to life. Our focus on durability, comfort, and aesthetics results in customized fabrics that reflect your vision and meet your specific needs.

YARN TREATMENT

It all starts with yarn. Located in the heart of textile country of China, Fabknitter mostly focuses on all types of polyesters fabrics (POY, DTY, FDY..), which could be manufactured or processed based on customer’s varying demands. This location allows us to leverage our knowledge with that of our supply partners and fosters the development of new yarn blends and technologies.

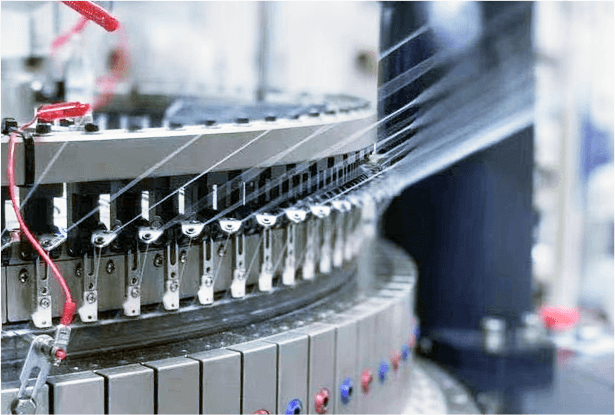

FABRIC KNITTING

At FabKnitter, currently we own more than 200 sets knitting machines including tubular and open width types. We can produce single-faced (jersey, terry, pique, three thread fleece,etc.), double-faced (Interlock, rib, scuba, eyes-bird etc.) and jacquard ( mattress, sports shirt) fabrics. And every fabric roll will be passed testing under our inspector controls.

FABRIC DYEING

Colors bring fabric into life. We only work with best dye houses to ensure the highest quality and most consistent dye processing, which needs to use low impact dyes to decrease environmental consumption and meet industry standards.

FABRIC FINISHING

Fabknitter offers state-of-the-art finishing techniques that insure the performance and hand-feel of our materials meet our customers specifications.

We adjust the width, weight, gsm, touch and shrinkage of the fabric according to the client's wanted properties, and use environmentally friendly chemicals to control the touch feel and functionalities of the fabric.

QUALITY CONTROL

We are familiar with the testing standards of various countries and regions. Every each roll of fabric is inspected by quality control department right after knitted. In-Process Quality Control is also necessary during dyeing and finishing processes, which include colour controlling, dimensional change after washing-shrinkage, spirality after washing, hand feeling-touch, colour fastness, water fastness, perspiration fastness, rubbing fastness, pilling resistance test, pH, GSM, width and tensile strength tests.

Contact us

Our team at FabKnitter is dedicated to providing exceptional customer service. We welcome any inquiries, feedback or comments you may have. Please do not hesitate to contact us via phone, email or using the contact form on our website. We are always happy to assist you.

- info@fabknitter.com

- kathy@fabknitter.com

- +86 157 1155 6000

- +86 (0)592 - 521 6737